The production cycle includes wax melting, fragrance blending, molding, and packaging. In March, the molding department accumulates $50,000 in direct material costs for wax and essential oils and $90,000 in conversion costs, covering wages, facility rent, and overhead. The total number of units produced for the month is 100,000 candles. Job order costing is used when a company produces unique, custom-made products or services. Each job is distinct from the other, and costs can be traced to each individual job. For example, a printing company that produces custom wedding invitations would use job order costing.

5.2 FIFO Cost Allocation (STEP #

The customer simply pulls up in a designated spot at Maria’s and the food is brought to their car, packaged, and ready to take home to enjoy. The system of costing conceals weaknesses and inefficiencies in processing. Cost Control – Being each process is standardised and stable unearned revenue and can be predetermined so control is easier. Transfer – In the contract costing every contract is separate and independent from each job or contract. Output of one process, becomes input for the next process till it reaches to finished product.

Weighted average costs

Instead, accountants compute the cost per unit by first accumulating costs for the entire period (usually a month) for each process or department. Second, they divide the accumulated costs by the number of units produced (tons, pounds, gallons, or feet) in that process or department. BrightLens Optical produces disposable contact lenses through multiple production stages, including polymer mixing, lens shaping, sterilization, and packaging. Since production runs continuously, some lenses remain in process at the end of each period. To ensure accurate cost allocation, the company accounts for Work-in-Process (WIP) inventory alongside completed units.

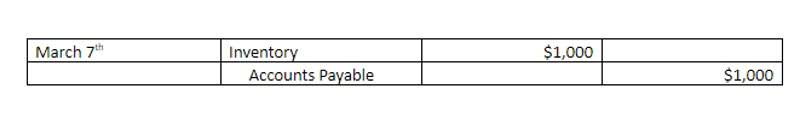

- Then, throughout the current period, the department incurs more costs that are debited to WIP.

- Direct materials are raw materials that become part of the finished product.

- Understanding these can help businesses determine if it’s the right approach for their cost management needs.

- Some manufacturers produce large quantities of identical units, such as bricks.

- This method is simpler to calculate and works well when costs remain relatively stable from period to period.

- This can help a business know how much money is committed to work-in-process inventory.

Divide Overhead

- However, it’s also the least accurate as it includes incomplete production units.

- Process loss is borne by joint products in the ratio of their output-weight.

- The finished product of one process is the raw material for the next process and this procedure continues until the final product arrives.

- Equivalent units account for the work done so far on the incomplete items and help you accurately allocate costs.

- I explained, above, FIFO’s Step #3 using what’s called the subtractive method.

Units in WIP must be converted to https://www.bookstime.com/ a base which can be equated with completed production. In a manufacturing unit generally it is not possible to complete the work on all the units on which work has been started. When there is abnormal gain, the process and units representing normal loss fetch some scrap value.

While process costing is simpler, ABC provides deeper cost insights. Process cost allows an organisation to assigns the cost to different steps in the production phase. The organisation can use this method to identify the relevant costs (i.e., direct and indirect costs) for each process, and no abnormal expenses are charged to any process. A product may be manufactured through one process or more than one process.

Process costing finds applications across numerous industries where standardized products flow through sequential processes. Food processing companies use it to track costs from raw ingredients through cooking, packaging, and distribution. Chemical manufacturers apply process costing to track costs through mixing, heating, cooling, and packaging stages. A process cost system (process costing) accumulates costs incurred to produce a product according to the processes or departments it goes through on its way to completion.

Presentation of Process Costs

Manufacturing overhead refers to indirect costs incurred during the production process that cannot be directly attributed to specific units of output. These costs include expenses such as utilities, maintenance, depreciation of machinery, and factory rent. On the other hand, process costing aggregates costs over a continuous production cycle. Instead of tracking costs for individual jobs, process costing focuses process costing on assigning average costs to each unit produced during a period.

- This flexibility allows businesses to optimize their costing approach based on specific circumstances.

- So when these firms allocate overhead, they also allocate direct materials and direct labor, i.e. all product costs.

- There can be abnormal gain also when the actual production is more than the expected production.

- Since the products are very similar in nature, different departments specialize in different processes.

- These costs include expenses such as utilities, maintenance, depreciation of machinery, and factory rent.

In so many organisations the management may decide to transfer the product of one process to the next process not at the cost of production but at the market price or by adding profit in the cost. The profit may be agreed percentage either on cost price or on transfer price. FIFO is used when the value of opening WIP is a lump sum figure and the degree of completion is not given. Average method is used when opening WIP is given in terms of materials, labour and overhead but the degree of completion is not mentioned.